Introduction

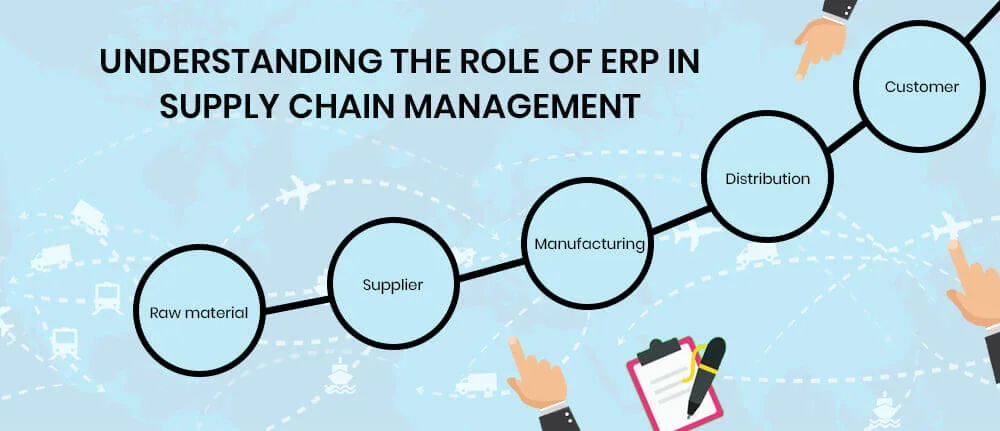

In an era where customer demands are constantly changing, and competition is fierce, supply chain management has become a strategic imperative for businesses. The ability to streamline operations, reduce costs, and deliver products or services efficiently can make all the difference in gaining a competitive edge. This is where ERP software comes into play.

What is ERP?

Enterprise Resource Planning (ERP) software is a comprehensive, integrated suite of applications that help businesses manage various aspects of their operations, including finance, human resources, procurement, manufacturing, and, of course, supply chain management. ERP systems provide a centralized database and a unified platform that enables real-time data sharing across different departments and functions within an organization.

The Key Role of ERP in Supply Chain Management

Inventory Management: One of the primary challenges in supply chain management is maintaining the right level of inventory. Too much stock ties up capital, while too little can result in stockouts and unhappy customers. ERP software provides sophisticated inventory management tools that help businesses optimize stock levels. With real-time data on inventory turnover rates, demand forecasting, and reorder points, companies can ensure that they have the right amount of stock on hand.

Demand Forecasting: Accurate demand forecasting is essential for supply chain planning. ERP systems use historical data and advanced algorithms to predict future demand trends. This information helps businesses align their production schedules and procurement activities with actual market demand, reducing overproduction and minimizing waste.

Streamlined Procurement: ERP software streamlines the procurement process by automating purchase orders, supplier management, and invoice processing. This not only saves time but also ensures that businesses get the best prices from their suppliers. Additionally, it helps in identifying and addressing supply chain bottlenecks or disruptions promptly.

Supply Chain Visibility: ERP systems offer real-time visibility into the entire supply chain. This means that businesses can track the movement of goods from suppliers to customers, monitor lead times, and identify potential delays or issues. Such visibility enables proactive decision-making, allowing companies to reroute shipments or adjust production schedules to minimize disruptions.

Cost Reduction: Effective supply chain management is all about cost control. ERP software helps in identifying areas where costs can be reduced, such as optimizing transportation routes, reducing excess inventory, and minimizing manual data entry errors. By eliminating inefficiencies, businesses can lower their operational costs and improve profitability.

Data Analytics: ERP systems collect vast amounts of data, which can be analyzed to gain valuable insights. By leveraging data analytics, companies can identify trends, performance metrics, and areas for improvement in their supply chains. These insights enable continuous process improvement and strategic decision-making.

Conclusion

In today’s highly competitive business environment, supply chain management is a critical function that can make or break a company’s success. ERP software plays a pivotal role in enhancing supply chain efficiency, from inventory management and demand forecasting to procurement and cost reduction. By investing in a robust ERP system, businesses can achieve better visibility, optimize their operations, and stay ahead of the competition in the complex world of supply chain management.