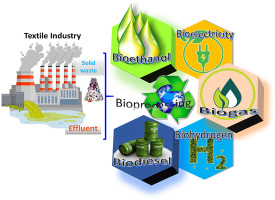

In a world increasingly aware of the environmental impact of its actions, industries across the globe are taking steps to reduce their carbon footprint. The textile industry, one of the largest and most resource-intensive sectors, is no exception. This blog post explores the intersection of renewable energy and sustainable textiles, highlighting how these two forces can work together to create a more eco-friendly future.

The Textile Industry’s Environmental Impact

Before we dive into the positive changes brought about by renewable energy, it’s crucial to understand the environmental challenges posed by the textile industry. As one of the largest industrial polluters globally, this sector contributes significantly to climate change, water pollution, and resource depletion.

Energy Consumption

The textile industry is notorious for its high energy consumption. From spinning and weaving to dyeing and finishing, every stage of the production process demands enormous amounts of electricity and heat. Traditionally, this energy has been derived from non-renewable sources such as fossil fuels, which release greenhouse gases into the atmosphere.

Water Usage

Water scarcity is a pressing global issue, and the textile industry exacerbates the problem. It takes thousands of liters of water to produce just one kilogram of cotton, and the dyeing and finishing processes can be equally water-intensive. Moreover, the chemicals used in these processes can contaminate water sources, posing risks to both the environment and human health.

Waste Generation

Textile waste is another serious concern. Fast fashion trends have led to a “throwaway culture,” where garments are discarded after only a few wears. This results in vast amounts of clothing ending up in landfills, where they can take decades to decompose.

The Role of Renewable Energy

The integration of renewable energy sources into textile production is a game-changer for the industry. Here’s how it works and the benefits it offers:

Solar Power

Solar panels are being increasingly installed in textile factories to harness the power of the sun. By converting sunlight into electricity, these panels reduce the reliance on fossil fuels. Some textile companies even invest in on-site solar farms, enabling them to generate their electricity sustainably.

Wind Energy

Wind turbines are another renewable energy source that textile manufacturers are embracing. By harnessing the power of wind, companies can produce electricity without emitting harmful pollutants. Wind farms are especially effective in areas with consistent wind patterns.

Hydropower

Hydropower, generated from flowing water, is utilized in some textile mills situated near rivers or water bodies. This eco-friendly energy source helps reduce greenhouse gas emissions and water usage simultaneously.

Geothermal Energy

Geothermal energy, tapped from the Earth’s heat, is being explored as an energy source for textile factories. This renewable option offers a constant and reliable supply of electricity without relying on fossil fuels.

Advantages of Renewable Energy in Textile Manufacturing

Reduced Carbon Emissions: The most apparent advantage of renewable energy integration is the significant reduction in greenhouse gas emissions. By shifting away from fossil fuels, textile companies can minimize their contribution to global warming.

Lower Operating Costs: Over time, renewable energy sources can lead to cost savings for textile manufacturers. While the initial investment in solar panels or wind turbines may be high, the long-term benefits of lower electricity bills and tax incentives can outweigh the upfront expenses.

Improved Brand Reputation: Sustainability is increasingly becoming a focal point for consumers. Textile companies that adopt renewable energy and eco-friendly practices tend to attract environmentally conscious customers, enhancing their brand image.

Resource Conservation: Renewable energy adoption is often accompanied by better resource management. Textile companies are incentivized to optimize their production processes, reducing waste and water usage.

Sustainable Textiles: Beyond Energy

While renewable energy is a significant step towards sustainability in the textile industry, it’s important to note that it’s just one piece of the puzzle. Truly sustainable textiles encompass various aspects:

Material Selection

Choosing eco-friendly materials is fundamental. Organic cotton, bamboo, and recycled fibers are gaining popularity because they require fewer resources and reduce the environmental impact.

Dyeing and Finishing

The dyeing and finishing processes are notorious for their water and chemical usage. Sustainable alternatives, such as waterless dyeing technologies and non-toxic dyes, are being developed to mitigate these issues.

Circular Fashion

The concept of a circular fashion economy is gaining traction. This model encourages recycling, upcycling, and reusing textiles to extend their lifespan and reduce waste.

Transparency and Ethical Practices

Consumers are increasingly interested in knowing where and how their clothing is made. Brands that prioritize transparency and adhere to ethical labor practices are better positioned to thrive in the sustainable fashion landscape.

The Way Forward

The synergy between renewable energy and sustainable textiles holds immense promise for the textile industry. As more companies adopt eco-friendly practices, the entire supply chain becomes more sustainable. However, this transformation requires collaboration from various stakeholders, including manufacturers, consumers, and policymakers.

Consumer Awareness

Educating consumers about the environmental impact of their fashion choices is crucial. When shoppers make informed decisions and support sustainable brands, they drive change in the industry.

Regulatory Support

Governments play a pivotal role in promoting renewable energy and sustainable practices. Incentives, subsidies, and regulations can encourage textile manufacturers to adopt greener technologies.

Innovation and Research

Investment in research and development is essential to discovering new materials and technologies that further reduce the environmental impact of textile production.

In conclusion, the textile industry is at a critical juncture, where renewable energy and sustainable practices are reshaping its future. By reducing energy consumption, water usage, and waste generation, while also embracing eco-friendly materials and circular fashion principles, the industry can move towards a more environmentally responsible and socially conscious path. As consumers increasingly demand sustainable products, textile companies that prioritize these principles are not only reducing their environmental footprint but also ensuring their long-term viability in a rapidly changing world.