In today’s fast-paced business landscape, the role of a product manager has never been more critical. As technology evolves, customer expectations change, and competition intensifies, product managers must adapt and adopt methodologies that help them build successful products efficiently. One such approach that has gained significant traction in recent years is Lean Product Management. In this blog post, we will explore the principles and practices of Lean Product Management and how it can help you create products that customers love while minimizing waste and maximizing value.

Introduction

Lean Product Management is a product development approach inspired by Lean Manufacturing and the Agile methodology. It emphasizes the importance of continuous improvement, customer feedback, and delivering value while minimizing waste. Lean thinking has been instrumental in transforming various industries, and its application to product management has yielded impressive results for companies of all sizes.

At its core, Lean Product Management focuses on achieving three main goals:

Minimize Waste: Waste in product development can take many forms, such as building features that customers don’t need or spending excessive time on planning and documentation. Lean Product Management aims to identify and eliminate these wasteful activities, ensuring that resources are used efficiently.

Maximize Value: The ultimate goal of any product is to provide value to customers. Lean Product Management prioritizes the delivery of features and improvements that have the most significant impact on customer satisfaction and business outcomes.

Learn Quickly: Lean Product Management encourages a culture of experimentation and learning. It emphasizes the importance of gathering customer feedback, testing hypotheses, and making data-driven decisions to iterate and improve the product continually.

Now, let’s explore the key principles and practices that drive Lean Product Management.

Principles of Lean Product Management

- Customer-Centricity

At the heart of Lean Product Management is a deep focus on the customer. Understanding customer needs, pain points, and preferences is essential for making informed product decisions. Product managers should engage with customers regularly through surveys, interviews, usability testing, and other feedback mechanisms.

- Build-Measure-Learn

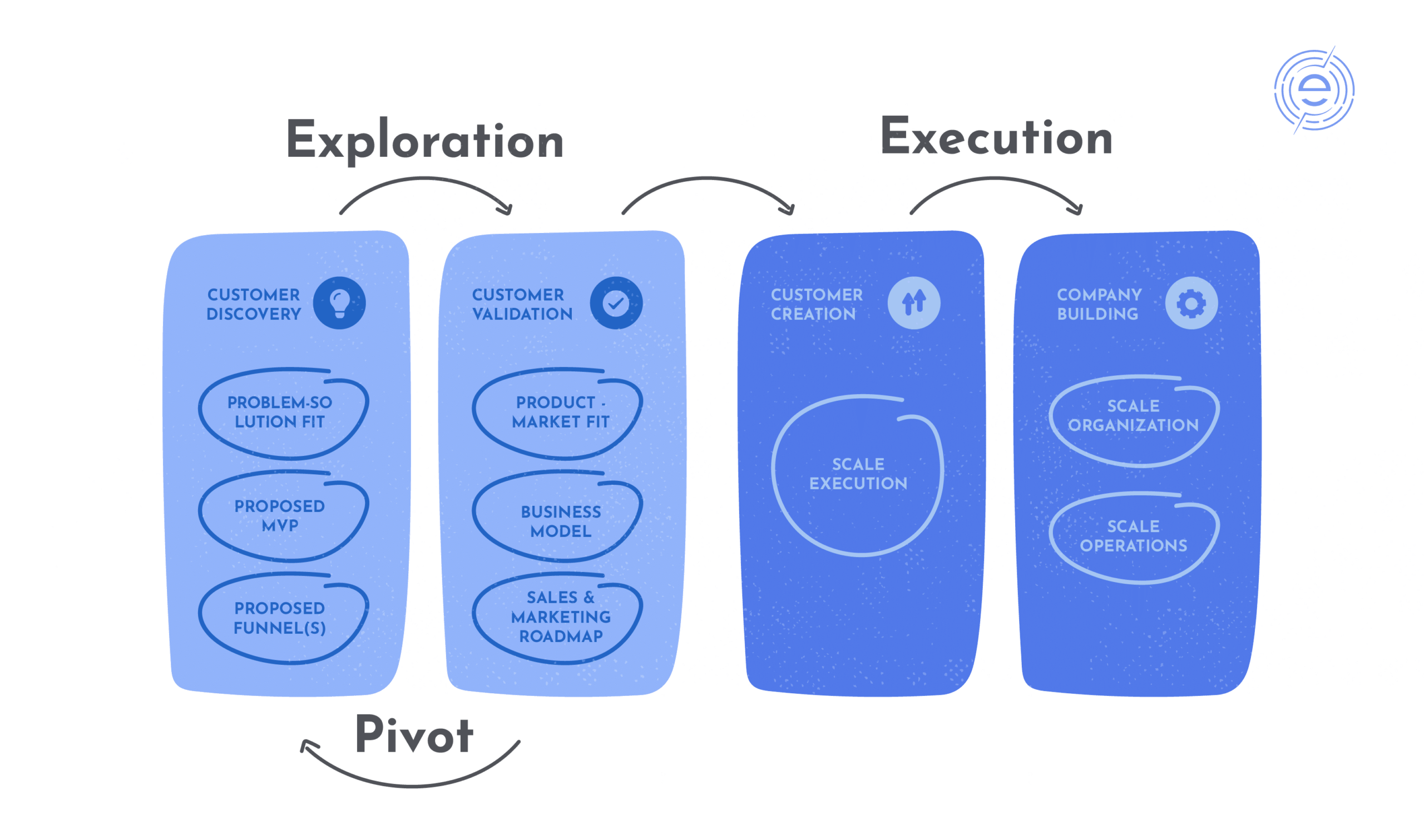

The Build-Measure-Learn cycle, often associated with Lean Startup methodology, is a fundamental principle of Lean Product Management. It involves building a minimum viable product (MVP), measuring its performance, and learning from the results. This iterative approach allows product teams to validate assumptions, refine their ideas, and pivot if necessary.

- Continuous Improvement

Lean Product Management embraces the philosophy of continuous improvement. Product managers should constantly seek ways to enhance the product, processes, and team performance. Regular retrospectives and post-mortems help identify areas for improvement and enable teams to adapt and evolve.

- Small Batches

Instead of working on large, monolithic releases, Lean Product Management encourages breaking down work into smaller, manageable batches. This approach reduces the risk of failure, allows for quicker testing and validation, and enables teams to respond to changing market conditions more effectively.

Practices of Lean Product Management

- Lean Canvas

A Lean Canvas is a one-page business model that helps product managers and teams visualize their product concept, target audience, key metrics, and value proposition. It serves as a quick and accessible reference point for aligning the team’s efforts with customer needs and business goals.

- A/B Testing

A/B testing involves comparing two or more versions of a feature or element to determine which performs better in terms of user engagement, conversion rates, or other relevant metrics. By systematically testing different ideas, product managers can make data-driven decisions and optimize the product based on user behavior.

- Minimum Viable Product (MVP)

An MVP is the smallest version of a product that can be released to the market while still providing value to early adopters. It allows product teams to validate their ideas with real users and gather valuable feedback without investing excessive time and resources.

- Kanban Boards

Kanban boards are visual tools used to manage and track work in progress. They help teams visualize their workflow, identify bottlenecks, and prioritize tasks. Kanban boards are particularly useful for managing small batches of work and ensuring that the team stays focused on delivering value.

Conclusion

Lean Product Management is not a one-size-fits-all solution, but rather a set of principles and practices that can be adapted to suit the specific needs and challenges of your organization. By embracing customer-centricity, prioritizing value, and fostering a culture of continuous improvement, product managers can navigate the complexities of modern product development with agility and effectiveness.

In a world where change is constant and competition is fierce, Lean Product Management provides a solid framework for building products that delight customers and drive business success. Whether you’re a seasoned product manager or just starting in the field, incorporating Lean principles and practices into your workflow can make a significant difference in your ability to innovate, iterate, and thrive in the dynamic landscape of product development.