Additive manufacturing, also known as 3D printing, is transforming the way products are designed, developed, and manufactured. This technology is particularly useful for rapid prototyping and product development, as it offers a range of benefits that can help companies bring new products to market more quickly and efficiently.

In this post, we’ll take a closer look at how additive manufacturing is used in rapid prototyping and product development, and explore some of the key advantages and challenges associated with this technology.

How Additive Manufacturing Works

Before we dive into the applications of additive manufacturing in rapid prototyping and product development, let’s first take a quick look at how this technology works.

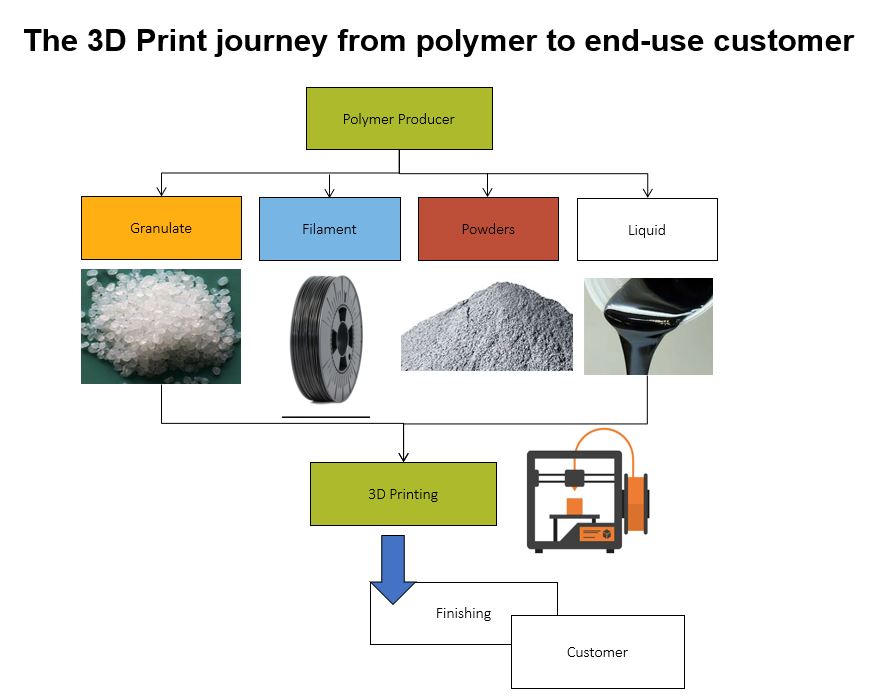

Additive manufacturing involves building objects layer by layer, using a 3D printer that reads a digital file and deposits material to create the final product. There are several different types of additive manufacturing processes, including:

Fused Deposition Modeling (FDM)

Stereolithography (SLA)

Selective Laser Sintering (SLS)

Digital Light Processing (DLP)

Each of these processes has its own unique advantages and limitations, and companies will typically choose the process that best suits their specific needs.

Applications of Additive Manufacturing in Rapid Prototyping and Product Development

Now that we have a basic understanding of how additive manufacturing works, let’s explore some of the key applications of this technology in rapid prototyping and product development.

- Faster Production Times

One of the key advantages of additive manufacturing is its ability to produce parts and prototypes more quickly than traditional manufacturing methods. Because 3D printing involves building objects layer by layer, there is no need for time-consuming tooling or mold-making processes. This means that companies can produce prototypes and parts in a matter of hours or days, rather than weeks or months. - Increased Customization Options

Another advantage of additive manufacturing is its ability to offer increased customization options. Traditional manufacturing methods often require companies to produce large quantities of identical parts, which can limit their ability to customize products for individual customers. With additive manufacturing, companies can produce unique, customized parts and products on demand, without incurring the costs associated with tooling or mold-making. - Reduced Costs

Additive manufacturing can also offer significant cost savings over traditional manufacturing methods. Because 3D printing eliminates the need for tooling and mold-making, companies can save money on materials, labor, and equipment. Additionally, because additive manufacturing is a more efficient process than traditional manufacturing, it can help companies reduce waste and improve overall production efficiency. - Improved Design and Testing Capabilities

Finally, additive manufacturing can help companies improve their design and testing capabilities. With 3D printing, companies can quickly produce multiple iterations of a product or prototype, allowing them to test and refine their designs more quickly and accurately than with traditional manufacturing methods. This can help companies bring better products to market more quickly and efficiently.

Challenges and Considerations

While additive manufacturing offers a range of benefits for rapid prototyping and product development, there are also some challenges and considerations that companies need to be aware of. These include:

Materials: Not all materials are suitable for additive manufacturing, and companies may need to invest in specialized materials and equipment to take full advantage of this technology.

Size: Most 3D

Additionally, AM can also help reduce the cost of product development by allowing companies to quickly and easily test out different designs without the need for expensive tooling. This can lead to faster time-to-market and a greater ability to meet customer demands.

Overall, additive manufacturing is transforming the way that companies approach product development and rapid prototyping. By allowing for greater design flexibility, faster iteration, and lower costs, AM is empowering businesses to bring new products to market more quickly and efficiently than ever before. As the technology continues to evolve and improve, it is sure to play an increasingly important role in the manufacturing landscape for years to come.