The mesmerizing world of 3D printing and additive manufacturing has taken us by storm in recent years. From creating intricate prototypes to producing customized consumer goods, this technology is a game-changer. But have you ever wondered how these 3D printers and additive manufacturing machines work their magic? The answer lies in a crucial but often overlooked component: firmware.

In this article, we will unravel the mysteries of firmware development for 3D printing and additive manufacturing. We’ll delve into its significance, the challenges faced by developers, and the exciting future that awaits this technology.

The Heart of the Machine: What is Firmware?

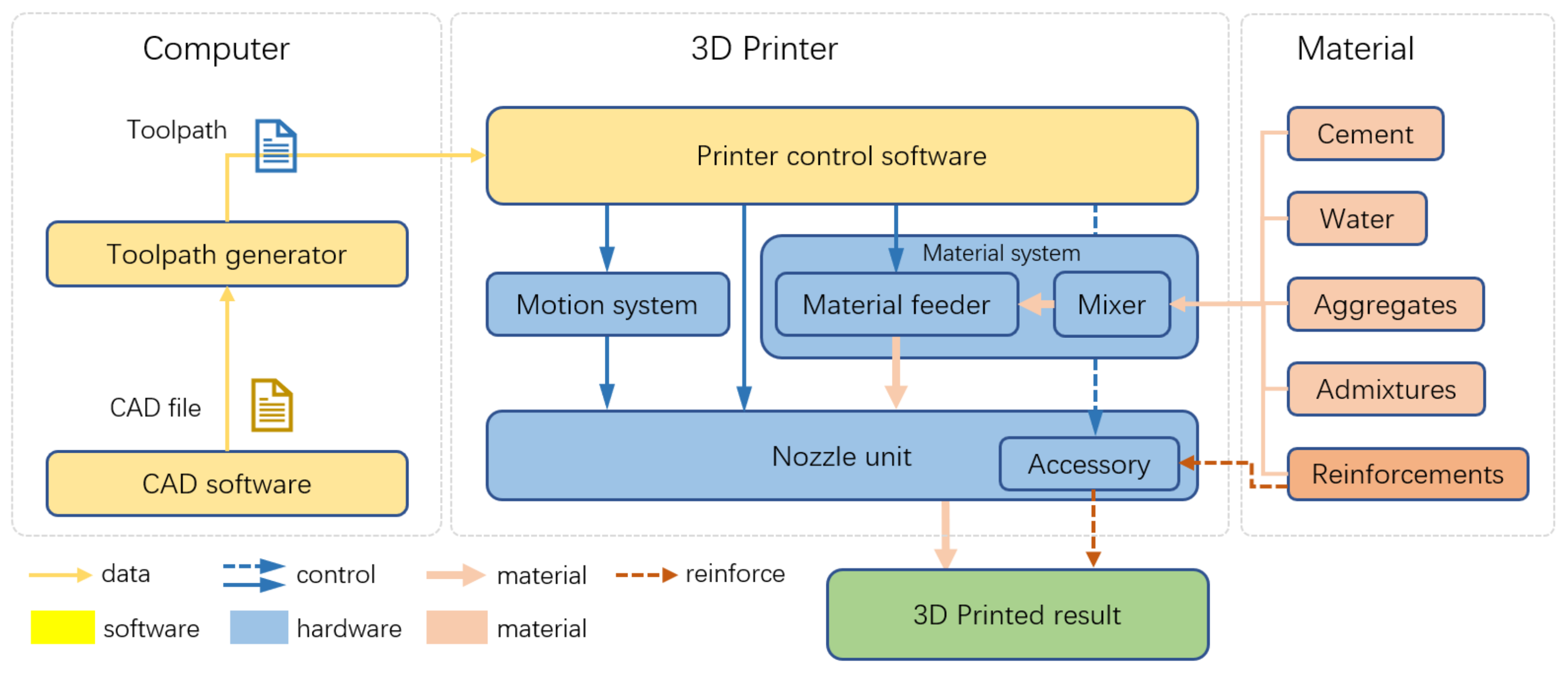

Before we plunge into the depths of firmware development, let’s first understand what firmware is. In the context of 3D printers and additive manufacturing machines, firmware refers to the specialized software that resides on the hardware of the machine itself. Unlike regular software, which is stored on a computer’s hard drive, firmware is permanently programmed into the machine’s memory, making it an integral part of the hardware.

The primary purpose of firmware in 3D printers and additive manufacturing machines is to control the hardware’s functions. It acts as the bridge between the digital design files and the physical creation process. When you send a 3D model to your printer, it’s the firmware that interprets the file and instructs the machine on how to build the object layer by layer.

Significance of Firmware in 3D Printing and Additive Manufacturing

Firmware may not grab the headlines, but it is undeniably the unsung hero of 3D printing and additive manufacturing. Here are some key reasons why firmware is so crucial in this industry:

- Precision and Accuracy

One of the most significant advantages of 3D printing and additive manufacturing is the precision they offer. Firmware plays a pivotal role in ensuring that each layer of material is deposited with pinpoint accuracy. This precision is essential for creating intricate and complex designs that meet industry standards. - Compatibility

3D printers come in various shapes and sizes, from desktop machines to industrial giants. Firmware acts as the universal translator, ensuring that design files can be processed and printed on different types of printers. It bridges the gap between diverse hardware and design software, making 3D printing accessible to a broader audience. - Optimization

Efficiency is key in manufacturing, and firmware helps optimize the printing process. It controls variables like print speed, temperature, and layer thickness to maximize the quality and reliability of the printed object. This optimization can lead to faster production times and reduced material waste. - User-Friendly Interface

For 3D printing to become more mainstream, it needs to be user-friendly. Firmware development includes creating intuitive user interfaces and control panels that enable users, even those with limited technical expertise, to operate the machines effectively. This ease of use is vital for the technology’s wider adoption.

Challenges in Firmware Development for 3D Printing

While firmware is undoubtedly essential, developing it for 3D printing and additive manufacturing is not without its challenges:

- Hardware Variability

As mentioned earlier, 3D printers come in a wide range of configurations. Developing firmware that works seamlessly across different hardware platforms is a daunting task. Firmware developers must account for various sensors, motors, and other components that can vary significantly from one machine to another. - Real-Time Processing

3D printing is a real-time process. The firmware must process design files and execute instructions in milliseconds to ensure that each layer is deposited accurately. This requires a high level of optimization and efficiency in the firmware code. - Continuous Updates

Technology never stands still, and neither does firmware development. Manufacturers frequently release updates to improve machine performance, add new features, or address security issues. Firmware developers must keep up with these changes and provide regular updates to keep the machines running smoothly. - Security Concerns

As 3D printing technology becomes more widespread, there is a growing concern about intellectual property theft. Firmware developers must implement security measures to protect design files and prevent unauthorized access to the machines.

The Future of Firmware in 3D Printing and Additive Manufacturing

So, what does the future hold for firmware development in 3D printing and additive manufacturing? Here are some exciting possibilities:

- AI Integration

Artificial intelligence (AI) has the potential to revolutionize firmware development. Machine learning algorithms can analyze real-time data from the printer and make on-the-fly adjustments to improve print quality and efficiency. - Cloud Connectivity

Cloud-based firmware updates and monitoring could become the norm. This would enable manufacturers to remotely diagnose and fix issues, update firmware, and even collaborate on projects in real-time. - Enhanced Security

With the increasing importance of intellectual property in the industry, firmware will need to incorporate robust security measures. This may include encryption, biometric authentication, and digital rights management (DRM) features. - Sustainability

Sustainability is a growing concern, and firmware can play a role in reducing waste and energy consumption. Future firmware updates may focus on optimizing printing parameters to minimize material usage and energy consumption.

Conclusion

Firmware development may not always be in the spotlight, but it is undeniably the backbone of 3D printing and additive manufacturing. Its role in ensuring precision, compatibility, optimization, and user-friendliness cannot be overstated. As technology continues to advance, firmware development will evolve to meet new challenges and opportunities, driving the 3D printing and additive manufacturing industry forward into a more innovative and sustainable future.