In the world of manufacturing, quality and consistency are the twin pillars that support the success of any product. Whether you’re producing automobiles, consumer electronics, or pharmaceuticals, ensuring that every item meets the highest standards is crucial for competitiveness and consumer satisfaction. Historically, achieving such levels of precision and consistency has been a formidable challenge, but today, thanks to automated manufacturing, these goals are becoming more attainable than ever before.

The Evolution of Manufacturing: From Handcrafting to Automation

Manufacturing has come a long way since the days of handcrafting goods, where skilled artisans meticulously shaped each item. While this approach allowed for a high degree of customization, it was also slow, labor-intensive, and often prone to errors. As industries grew and demand skyrocketed, a need arose for more efficient and consistent methods of production.

The first major shift towards automation occurred during the Industrial Revolution, with the advent of machines that could perform repetitive tasks. These machines, while a significant improvement over manual labor, still required human operators and were limited in their capabilities.

Fast forward to the present day, and we find ourselves in the midst of a technological revolution known as Industry 4.0. This era is characterized by the integration of automation, data exchange, and digital technologies into manufacturing processes. The result? A new level of precision, efficiency, and consistency that was once unimaginable.

The Role of Automation in Modern Manufacturing

Automation has permeated virtually every aspect of modern manufacturing. From assembly lines to quality control, it plays a pivotal role in ensuring that products meet the highest standards. Let’s explore how automation is driving improvements in quality and consistency across various industries:

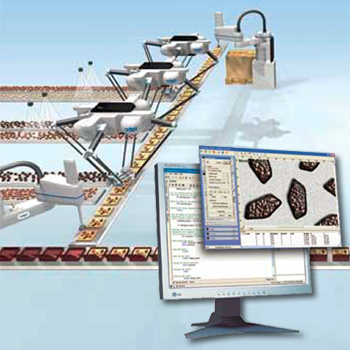

Automated Assembly Lines: Assembly lines are the heart of manufacturing, and automation has transformed them into well-orchestrated symphonies of efficiency. Robots and machines now perform tasks that were previously done by hand, resulting in faster production rates and reduced errors.

Precision Machining: In industries like aerospace and automotive, precision is paramount. Automated machining centers can produce intricate components with microscopic tolerances, ensuring that every piece fits perfectly into the final product.

Quality Control and Inspection: Automated systems equipped with cameras and sensors can inspect products at a level of detail that surpasses human capabilities. They can identify even the tiniest defects and deviations from specifications, allowing for immediate corrective actions.

Material Handling: Automation is not limited to the manufacturing process itself but extends to material handling and logistics. Automated guided vehicles (AGVs) and conveyor systems efficiently transport raw materials and finished products throughout the facility, reducing delays and errors.

Data Analytics and Predictive Maintenance: With the advent of the Internet of Things (IoT), machines are now equipped with sensors that collect vast amounts of data. This data can be analyzed in real-time to predict when maintenance is needed, preventing unexpected downtime.

Customization at Scale: Automated manufacturing doesn’t mean sacrificing customization. Advanced software and robotics allow for mass customization, where each product can be tailored to individual customer preferences while maintaining efficiency and consistency.

The Advantages of Automated Manufacturing

The adoption of automated manufacturing offers numerous advantages for businesses and consumers alike:

Consistency: Automation ensures that every product adheres to the same high-quality standards, reducing variability and defects.

Efficiency: Machines don’t tire, take breaks, or make mistakes due to fatigue. This leads to higher production rates and lower operational costs.

Safety: Dangerous and repetitive tasks can be assigned to machines, reducing the risk of accidents and improving workplace safety.

Reduced Waste: Automation minimizes material waste by optimizing processes and reducing errors, making manufacturing more environmentally friendly.

Competitive Advantage: Companies that embrace automation can deliver products faster, at a lower cost, and with higher quality, giving them a significant edge in the market.

Challenges and Considerations

While automated manufacturing offers a multitude of benefits, it also presents challenges and considerations that need to be addressed:

Initial Investment: Implementing automation can be expensive, requiring significant upfront capital for technology acquisition and integration.

Skills Gap: The transition to automation may necessitate retraining and upskilling of the workforce, which can be a logistical and cultural challenge.

Cybersecurity: As manufacturing becomes more connected, the risk of cyberattacks on automated systems increases. Robust cybersecurity measures are crucial.

Maintenance: Automated machines still require maintenance and occasional repairs, and downtime for maintenance must be carefully managed.

Ethical and Social Implications: The displacement of human workers by automation raises ethical and social questions that need careful consideration.

The Future of Automated Manufacturing

As technology continues to advance, the future of automated manufacturing looks promising. Emerging technologies like artificial intelligence, machine learning, and 3D printing are poised to further revolutionize the industry. These developments will lead to even greater levels of precision, customization, and efficiency.

In conclusion, automated manufacturing is not just a trend but a fundamental shift that is reshaping the landscape of industry. It empowers businesses to produce higher-quality products with greater consistency, ultimately benefiting consumers through improved products and competitive pricing. As we continue to embrace automation, the possibilities for innovation and growth in manufacturing are boundless, promising a future where quality and consistency are the norm rather than the exception.