Introduction

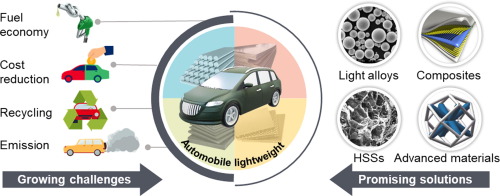

The automotive industry is undergoing a profound transformation. With environmental concerns and stricter fuel economy regulations, car manufacturers are racing to develop vehicles that are lighter, more fuel-efficient, and environmentally friendly. One of the key drivers of this transformation is materials science, which plays a pivotal role in lightweighting vehicles.

In this blog post, we will delve into the significance of materials science in the automotive industry and explore how advanced materials are shaping the future of transportation. From reducing carbon emissions to improving safety, materials innovation is at the forefront of automotive engineering.

The Challenge of Fuel Efficiency

Fuel efficiency has become a central concern for both consumers and car manufacturers. As the world grapples with the consequences of climate change, reducing carbon emissions has become a top priority. Lightweighting vehicles is a proven strategy to improve fuel efficiency, and this is where materials science comes into play.

Materials Revolutionizing the Industry

Advanced High-Strength Steel (AHSS)

Advanced high-strength steel is one of the unsung heroes of lightweighting. It offers exceptional strength-to-weight ratios, making it a favorite among automotive engineers. With AHSS, vehicles can maintain structural integrity while shedding excess pounds. This not only improves fuel efficiency but also enhances safety by providing better crash protection.

Aluminum Alloys

Aluminum is another material gaining prominence in the automotive industry. Its low density and excellent corrosion resistance make it an ideal choice for lightweighting vehicle components. From body panels to engine blocks, aluminum alloys are making cars lighter and more fuel-efficient.

Carbon Fiber Reinforced Polymers (CFRPs)

Carbon fiber composites have long been used in high-performance vehicles, but their application is expanding. CFRPs are incredibly strong and lightweight, making them perfect for components like body panels, chassis, and even entire vehicle structures. While cost remains a challenge, ongoing research is driving down production costs, paving the way for wider adoption.

Advanced Plastics

High-performance plastics are making inroads in automotive design. They are not only lighter than traditional materials but also offer excellent resistance to chemicals and corrosion. Interior components, such as dashboards and door panels, benefit from advanced plastics, contributing to overall weight reduction.

Safety Implications

Lightweighting is not just about improving fuel efficiency. It also has profound safety implications. Advanced materials allow manufacturers to design vehicles with enhanced crashworthiness. This means vehicles can be both lighter and safer, a win-win scenario for consumers and the environment.

Challenges and Future Prospects

While materials science has made significant strides in lightweighting vehicles, challenges remain. Cost considerations, recyclability, and the need for robust supply chains are all critical factors. However, with ongoing research and innovation, these challenges are gradually being overcome.

The future of lightweighting vehicles looks promising. Emerging technologies like 3D printing and nanomaterials offer new avenues for materials innovation. Additionally, as consumers increasingly demand eco-friendly transportation options, the automotive industry will continue to invest in sustainable materials.

Conclusion

In conclusion, materials science is playing a pivotal role in lightweighting vehicles, addressing the pressing issues of fuel efficiency, carbon emissions, and safety. From advanced high-strength steel to carbon fiber composites, innovative materials are transforming the automotive industry. As we move towards a more sustainable future, materials science will continue to drive progress in the quest for lightweight, eco-friendly vehicles. The road ahead is filled with exciting possibilities, and materials scientists are at the forefront of this automotive revolution.