SolidWorks: Transforming Industrial Design and Product Development

In the ever-evolving landscape of industrial design and product development, staying at the forefront of technology is paramount. SolidWorks, a household name among engineers, designers, and manufacturers, has proven to be a game-changer in the field. With its versatile capabilities and intuitive interface, SolidWorks has become a go-to software for those striving to turn innovative ideas into tangible products.

The Evolution of SolidWorks

SolidWorks, developed by Dassault Systèmes, was first introduced in 1995. Since its inception, it has undergone numerous transformations, consistently adapting to the changing demands of the industry. Today, it is recognized as one of the most advanced Computer-Aided Design (CAD) software solutions available.

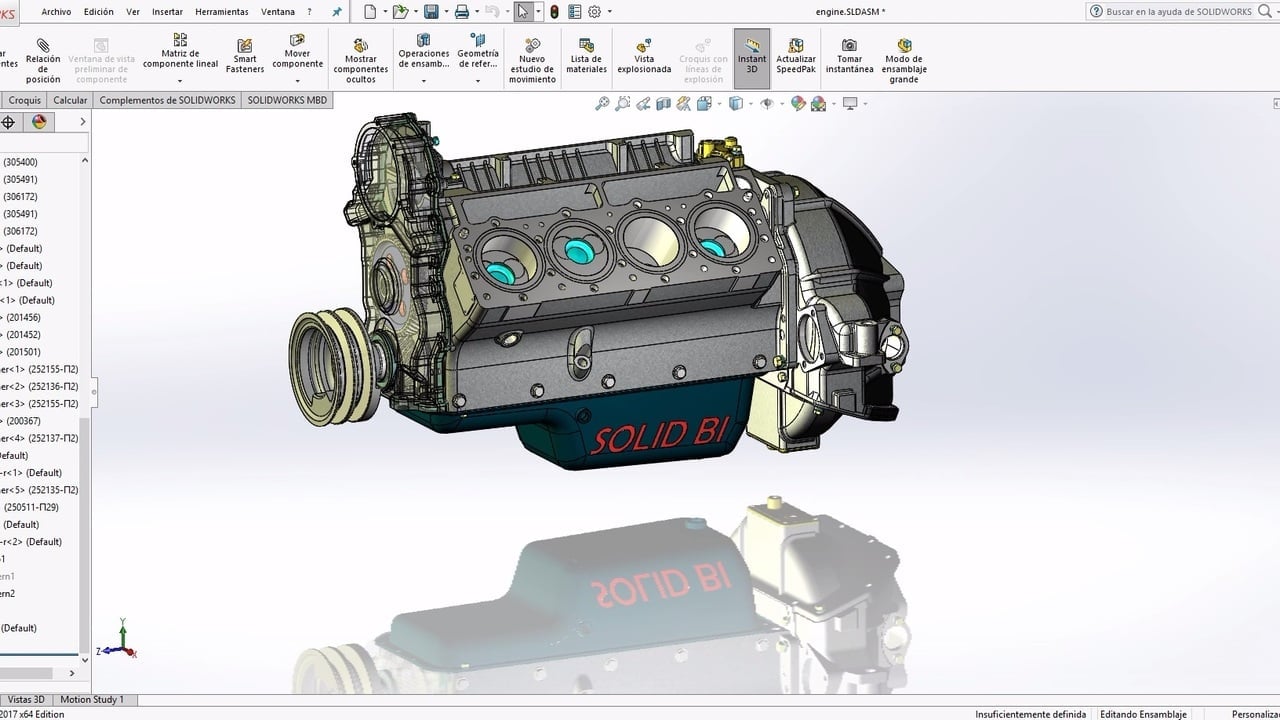

3D Modeling at Its Finest

At the heart of SolidWorks lies its robust 3D modeling capabilities. Unlike traditional 2D drafting, SolidWorks empowers designers to bring their ideas to life in a three-dimensional space. This not only enhances visualization but also streamlines the product development process.

One of the standout features of SolidWorks is its parametric modeling, which allows users to make changes at any stage of the design process without starting from scratch. This feature alone has saved countless hours and resources, making it a must-have for product designers.

User-Friendly Interface

One of the reasons behind SolidWorks’ widespread adoption is its user-friendly interface. Whether you’re a seasoned professional or a novice designer, the software’s intuitive layout makes it easy to learn and master. The drag-and-drop functionality, extensive library of pre-built components, and a plethora of online tutorials ensure that even beginners can quickly get up to speed.

Collaboration and Integration

In today’s interconnected world, collaboration is key. SolidWorks acknowledges this by offering various collaboration tools and integrations. Design teams can work seamlessly on the same project, regardless of their physical location. Additionally, SolidWorks easily integrates with other software tools commonly used in product development, further enhancing its versatility.

The Power of Simulation

SolidWorks isn’t just a modeling tool; it’s also a powerful simulation platform. With its integrated simulation capabilities, engineers can test their designs for factors like stress, vibration, and heat transfer. This allows for informed decision-making early in the design phase, reducing the risk of costly errors in the later stages of development.

Streamlining Manufacturing

Manufacturers also benefit from the use of SolidWorks. Its built-in tools for creating manufacturing drawings, Bills of Materials (BOMs), and even animations for assembly instructions simplify the process of turning designs into real-world products. This seamless transition from design to manufacturing helps companies reduce production costs and accelerate time to market.

Real-World Applications

SolidWorks is used in various industries, ranging from aerospace to automotive, consumer goods to medical devices. Here are a few examples of how this software is making a difference:

- Aerospace Industry

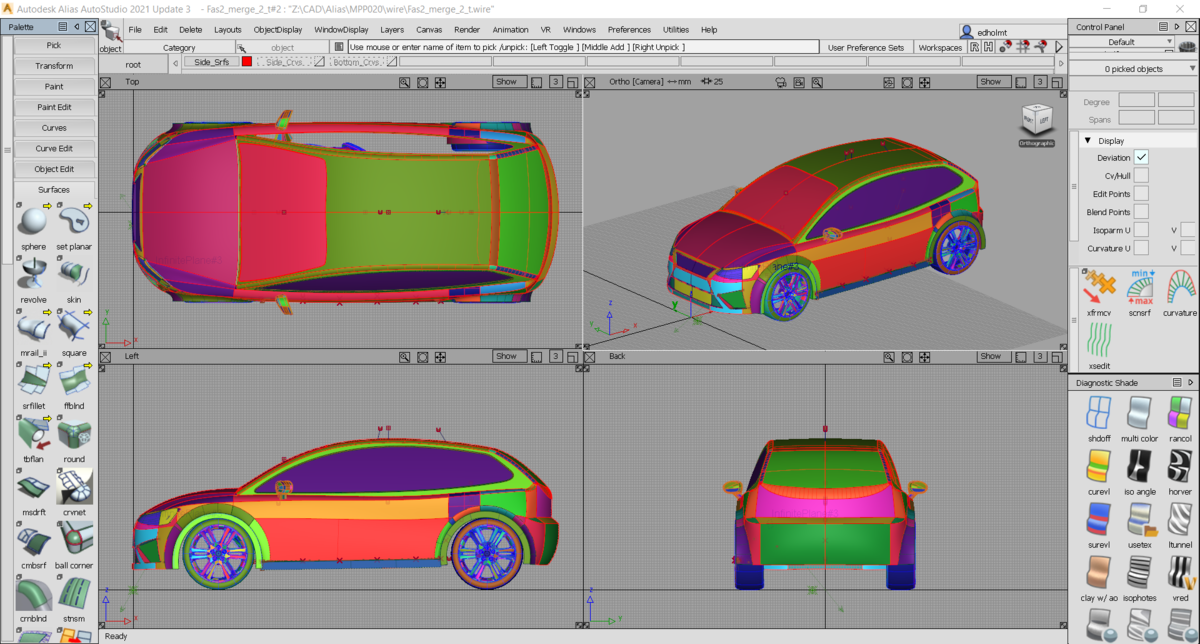

In the aerospace industry, precision and safety are paramount. SolidWorks enables aerospace engineers to create intricate designs with precision and to simulate the performance of complex systems. It has played a crucial role in developing cutting-edge aircraft and spacecraft. - Automotive Sector

Car manufacturers rely on SolidWorks to design not only the vehicles themselves but also the production lines that make them. The software’s ability to simulate assembly processes helps carmakers optimize efficiency and quality. - Medical Device Development

The medical industry benefits from SolidWorks by allowing designers to create life-saving equipment and devices with accuracy and reliability. From prosthetic limbs to diagnostic equipment, SolidWorks aids in the development of products that improve lives. - Consumer Electronics

The world of consumer electronics is fast-paced, with new products emerging constantly. SolidWorks helps designers keep up with this pace by allowing them to quickly iterate on designs and make adjustments based on user feedback.

The Future of SolidWorks

As technology continues to advance, so does SolidWorks. With each new release, the software brings innovative features and enhancements. The integration of virtual reality (VR) and augmented reality (AR) capabilities into SolidWorks opens up exciting possibilities for design and collaboration. Engineers can visualize their designs in 3D space, making it easier to spot potential issues and refine their creations.

In the age of sustainability, SolidWorks also plays a role in eco-friendly design. Its tools for materials analysis and lifecycle assessment aid in the creation of products that are not only functional and appealing but also environmentally responsible.

Conclusion

SolidWorks has become a cornerstone of industrial design and product development, revolutionizing the way engineers and designers work. Its 3D modeling capabilities, user-friendly interface, and powerful simulation tools have made it an indispensable asset in a variety of industries. As technology continues to evolve, SolidWorks will undoubtedly continue to adapt and innovate, further shaping the future of industrial design and product development. So whether you’re designing a spacecraft or the next groundbreaking gadget, SolidWorks is a name that’s sure to remain synonymous with success.