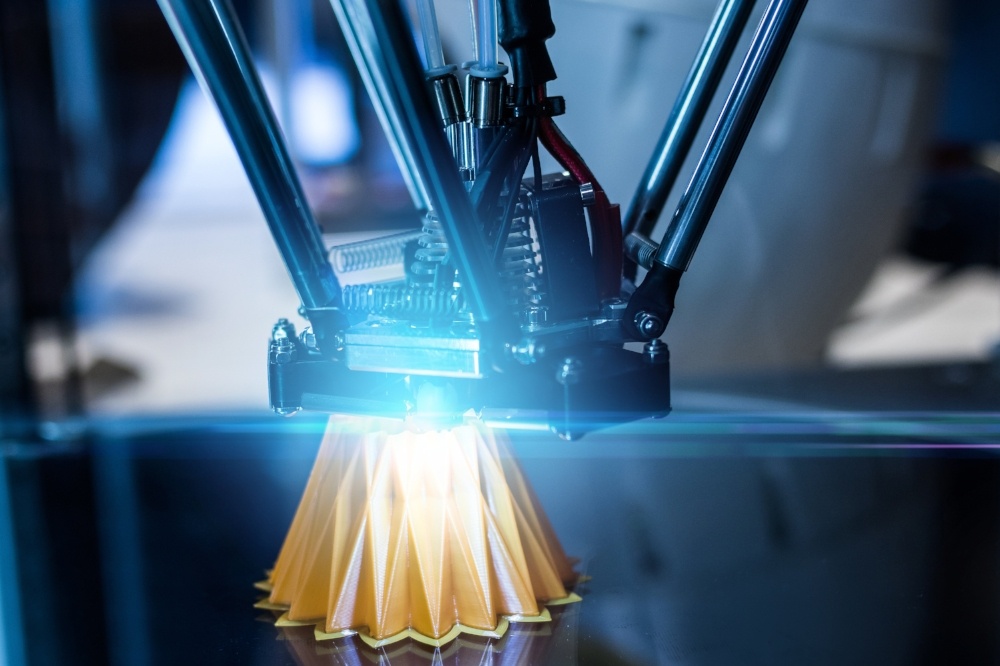

Additive manufacturing, also known as 3D printing, is a rapidly growing industry that is transforming the way products are designed and manufactured. By using digital designs to create objects layer by layer, 3D printing enables faster prototyping and customization, reduced material waste, and improved product quality. In this blog post, we’ll explore five industries that are benefiting from additive manufacturing.

Aerospace

The aerospace industry is one of the earliest adopters of additive manufacturing, and for good reason. With 3D printing, aerospace engineers can quickly and easily create complex parts that would be difficult or impossible to produce with traditional manufacturing techniques. Additive manufacturing also allows for lighter and more efficient designs, which can improve fuel efficiency and reduce costs.

Medical

The medical industry has also embraced additive manufacturing as a way to create customized products and devices. 3D printing allows medical professionals to create prosthetics, implants, and other medical devices that are tailored to the patient’s individual needs. Additionally, 3D printing can be used to create replicas of organs and other body parts for use in surgical planning and training.

Automotive

The automotive industry is another early adopter of additive manufacturing. With 3D printing, automotive engineers can quickly create prototypes of new designs and test them for performance and safety. Additionally, 3D printing can be used to create spare parts for older vehicles, reducing the need for expensive tooling and molds.

Architecture and Construction

Additive manufacturing is also being used in the architecture and construction industries to create complex and unique structures. 3D printing allows architects and engineers to create custom components and designs that would be difficult or impossible to produce with traditional construction methods. Additionally, 3D printing can be used to create molds and forms for concrete and other building materials.

Fashion

The fashion industry is also beginning to embrace additive manufacturing as a way to create unique and custom designs. With 3D printing, fashion designers can create intricate and complex pieces that would be impossible to produce with traditional manufacturing methods. Additionally, 3D printing allows for more sustainable fashion practices by reducing material waste and enabling on-demand production.

Conclusion

Additive manufacturing is revolutionizing many industries by providing new opportunities for product design and development. From the aerospace and medical industries to the automotive, architecture, and fashion industries, the possibilities are endless. As the technology continues to evolve and become more accessible, we can expect to see even more exciting applications of additive manufacturing in the years to come.