Introduction

The age of desktop manufacturing is upon us, and 3D printing is its herald. Once a niche technology, 3D printing has rapidly evolved to become a transformative force in various industries, from healthcare and aerospace to fashion and art. This article explores the marvel of 3D printing and how it is revolutionizing the way we design, create, and manufacture objects right from our desks.

Understanding 3D Printing

To grasp the significance of 3D printing, we must first understand the basics. 3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects layer by layer using a digital model as a blueprint. Unlike traditional subtractive manufacturing techniques, such as CNC machining, where material is removed from a solid block to form an object, 3D printing builds objects up, depositing material one layer at a time.

The Building Blocks: Materials and Technologies

Various materials are used in 3D printing, ranging from plastics and metals to ceramics and even organic compounds. The choice of material depends on the specific application and desired properties of the final product. For example, in aerospace, lightweight and strong materials like titanium are preferred, while in healthcare, biocompatible materials like PLA (Polylactic Acid) are used to create medical implants.

Different 3D printing technologies are available, each with its own unique approach and advantages. Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Digital Light Processing (DLP) are some of the most widely used methods. These technologies differ in the way they create layers, cure materials, and build objects, allowing for a wide range of applications.

Applications of 3D Printing

The versatility of 3D printing technology is astounding, and its applications span a wide spectrum of industries. Here are some notable applications:

Healthcare: 3D printing has revolutionized the medical field. Custom prosthetics, dental implants, and even 3D-printed organs are becoming a reality. Surgeons can practice complex procedures on patient-specific 3D-printed models, improving surgical outcomes.

Aerospace: The aerospace industry employs 3D printing to create lightweight and intricate components for aircraft and spacecraft. This technology reduces weight, increases fuel efficiency, and enhances performance.

Automotive: Car manufacturers use 3D printing for rapid prototyping and the production of specialized parts. It allows for more efficient vehicle design and customization.

Fashion: Designers are exploring 3D printing to create avant-garde fashion pieces and accessories. The technology enables intricate and geometric designs that were previously impossible to achieve.

Architecture: Architects use 3D printing to create scale models and intricate building components. It allows for greater precision in construction and design.

Education: 3D printing has found its place in schools and universities, inspiring creativity and innovation among students. It’s a valuable tool for teaching science, technology, engineering, and mathematics (STEM) concepts.

Art: Artists are pushing the boundaries of creativity with 3D printing, producing sculptures, installations, and interactive art pieces.

Consumer Products: Customization is at the heart of consumer 3D printing. From personalized phone cases to home decor, individuals can create unique items to suit their tastes.

The Desktop Revolution

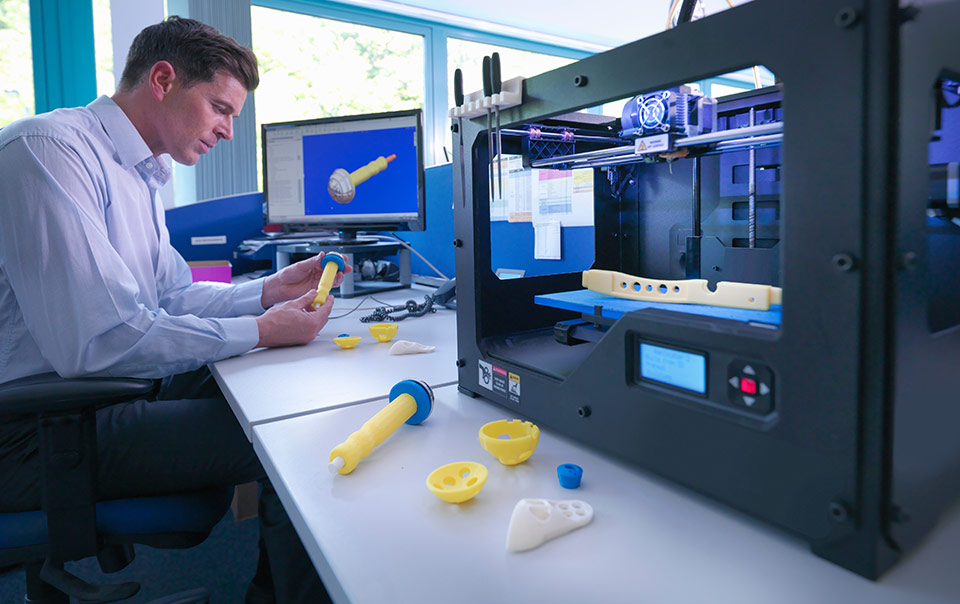

What’s truly exciting about 3D printing is the democratization of manufacturing. In the past, manufacturing was the domain of large factories and corporations. However, 3D printing is changing the landscape, allowing individuals and small businesses to create prototypes, products, and art pieces with relative ease.

Desktop 3D printers are now available at affordable prices, enabling hobbyists and entrepreneurs to experiment with the technology. These compact machines can sit on your desk and bring your ideas to life. Software tools like Tinkercad and Fusion 360 make designing 3D models accessible to anyone with a computer.

The availability of open-source 3D printing designs and a supportive online community mean that knowledge sharing is at the heart of this technology. Users can access and modify existing designs, making it easier for newcomers to get started and for experienced users to collaborate and innovate.

Challenges and Future Prospects

While the potential of 3D printing is vast, it’s not without its challenges. Material limitations, post-processing requirements, and copyright issues are some of the hurdles that need to be addressed. Furthermore, ensuring the safety and quality of 3D-printed medical implants and aerospace components is critical.

As technology continues to advance, we can expect to see exciting developments in the world of 3D printing. These may include:

Multi-material Printing: Advancements in technology will allow the simultaneous use of different materials, opening up new possibilities in manufacturing.

Bioprinting: The field of bioprinting is advancing rapidly, with the potential to create functional organs and tissues for transplantation.

Sustainability: Researchers are working on 3D printing with recycled and biodegradable materials, reducing the environmental impact.

Space Exploration: 3D printing is playing a crucial role in space missions, enabling astronauts to print tools and components in the harsh conditions of space.

Conclusion

The world of 3D printing and desktop manufacturing is an exciting frontier in technology. It has already transformed industries and is set to redefine how we approach design and manufacturing in the future. As this technology becomes more accessible, we can look forward to a world where individuals and small businesses have the power to turn their ideas into tangible reality, all from the comfort of their desks.

The key to harnessing the potential of 3D printing lies in continued research, innovation, and responsible use. As we navigate the challenges and opportunities presented by this technology, one thing is clear: the future of manufacturing is here, and it’s as close as your desktop.